METHOD MAY FINALLY UNLEASH GRAPHENE FOR FASTER COMPUTERS

A brand-new technique might obtain graphene an action better towards changing less-effective copper interconnects in the world's computer system gadgets.

Since researchers found graphene, the versatile, two-dimensional type of graphite (believe a 1-atom-thick sheet of pencil lead), in 2004, scientists worldwide have actually been actually functioning towards establish readily scalable requests for this high-performance product.

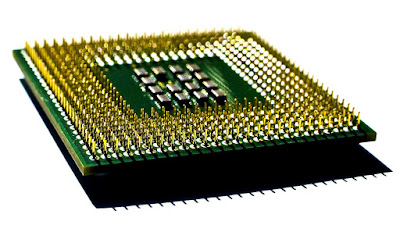

Graphene is actually one hundred towards 300 opportunities more powerful compared to steel as well as has actually an optimum electric present thickness purchases of size higher than that of copper, creating it the greatest, thinnest as well as, without a doubt, one of the absolute most dependable electrically conductive product in the world. It is actually, for that reason, an incredibly guaranteeing product for interconnects, the essential elements that link billions of transistors on microchips in computer systems as well as various other digital gadgets in the contemporary globe.

mix parlay kesempatan menang besar judi bola 1x2

THE PROBLEM WITH COPPER

For over twenty years, interconnects have actually been actually made from copper, however that steel experiences essential bodily restrictions as electric elements that integrate it diminish towards the nanoscale.

"As you decrease the measurements of copper cables, their resistivity shoots up," states Kaustav Banerjee, a teacher in the electric as well as computer system design division at the College of California, Santa Barbara. "Resistivity is actually a product residential or commercial home that isn't expected towards alter, however at the nanoscale, all of residential or commercial homes alter."

As the resistivity enhances, copper cables produce much a lot extra warm, decreasing their current-carrying capability. It is an issue that positions an essential risk towards the $500 billion semiconductor market. Graphene has actually the prospective towards refix that as well as various other problems. One significant challenge, however, is actually developing graphene microcomponents that could be produced on-chip, on a big range, in an industrial factory.

"Whatever the element, be actually it inductors, interconnects, aerials, or even everything more you wish to finish with graphene, market will certainly progress using it just if you discover a method towards synthesize graphene straight into silicon wafers," Banerjee states. He discusses that production procedures associated with the transistors, which are actually created very initial, are actually described as the ‘front point.' Towards synthesize one thing at the back-end—that is actually, after the transistors are actually fabricated—you deal with a limited thermal budget plan that cannot surpass a temperature level of around five hundred levels Celsius.

If the silicon wafer obtains as well warm throughout the back-end procedures utilized towards produce the interconnects, various other aspects that are actually currently on the potato chip might obtain harmed, or even some pollutants might begin diffusing, altering the qualities of the transistors.

Currently, after a decade-long mission towards accomplish graphene interconnects, Banerjee's laboratory has actually industrialized a technique towards execute high-conductivity, nanometer-scale doped multilayer graphene (DMG) interconnects that work along with high-volume production of incorporated circuits.